Looking for AAC block as alternative brick? Here’s what you need to know

What is AAC (Autoclaved Aerated Concrete)? AAC is a pre-manufactured substance consisting of primarily concrete, a proportion of lime, fine aggregates, water, and an expanding agent, is suitable for constructing both load-bearing walls and partition walls. It has been applied in a range of building applications; walls, floors, roofs, shaft walls, sound walls, privacy fences, and mining applications for light-weighted, energy-saving and environmental-friendly.

1.Compare to normal brick, AAC blocks offer a multitude of advantages, including superior fire insulation, significantly improved thermal efficiency, and the micro-pores effectively serve as excellent acoustic insulators for buildings.

Traditional clay bricks excel at heat absorption but struggle to effectively dissipate it due to their solid structure. Conversely, AAC blocks, though solid in form, benefit from pores that facilitate heat dissipation, allowing them to “breathe.” Its thermal efficiency effectively insulates the interior of the building from heat, and in the event of a fire, it also provides protection by withstanding high temperatures.

Also, the alternate purpose of micropores is to absorb sound, acting like a sponge between the exterior and interior. It has been demonstrated that they are effective in reducing noise.

2. While it may have a slightly higher upfront cost, AAC block’s labor efficiency makes the overall cost lower than ordinary bricks.

Regular bricks require one worker a day to install 1 square meter, whereas AAC is more material-efficient, eliminating the need for plaster and only requiring screeding. It also saves time, as one labor worker can construct more walls compared to the usual process.

AAC blocks are accurate in dimension that it is very easy to layer it well. Nice brick work means your wall can score higher in Qlassic or Conquas score!

3. For environmental supporter like us, AAC blocks are also environmentally friendly.

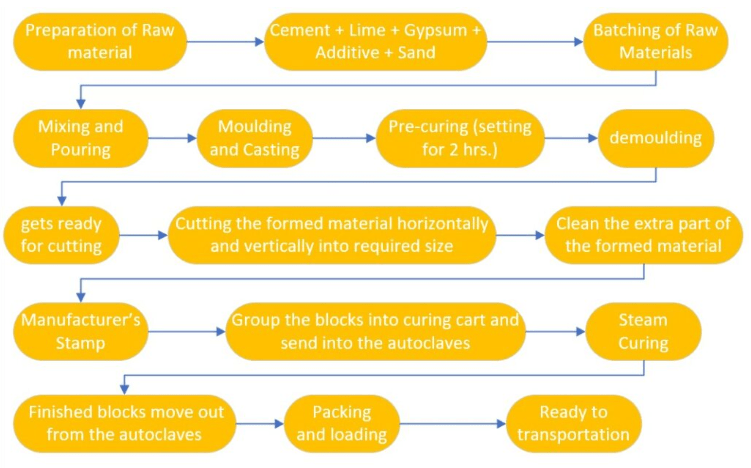

Manufactured through industrial production, AAC Block is created using a formulation consisting of concrete, a proportion of lime, fine aggregates, water and an expanding agent. This industrial process minimizes waste, has a minimal environmental impact, and remains highly efficient in its production.

Compare to AAC, the normal clay brick is made with a combination of sand, aggregate and cement. The primary aggregate is typically limestone. The main process involves digging, grinding, forming and firing, the firing process can produce emissions and ash residues.

(Source: civilsolution.in)

TLDR version of AAC blocks is summarized in the following table.

| AAC blocks | Clay brick | |

|---|---|---|

| Eco-friendly | ✅ | – |

| Dry density | ✅ | ✅ |

| Compressive strength | – | ✅ |

| Insulation properties | ✅ | ✅ |

| Weight | ✅ | – |

| Thermal conductivity | ✅ | – |

More information by Alam-con

Learn more about Alam-con products from the following featured content,

Alam – Con Sdn Bhd is the latest local company involves in the manufacturing of Autoclaved Aerated Concrete (AAC). It’s manufacturing plant is located in Kawasan Perindustrian Bukit Rambai Melaka and commenced its first production in early January 2012.

The target market includes individual houses, link houses and condominiums in the medium to high cost area, low rise commercial projects such as hotels, shops and offices, schools, hospitals and industrial buildings.

Note: To protect our designers & suppliers community from spam and harassment. Your contact requested will be routed to Buildex.my representative. We will connect you to the representative asap.